Our Services

Printing on Paper,

Plastic, Metal, Clothing,

and More.

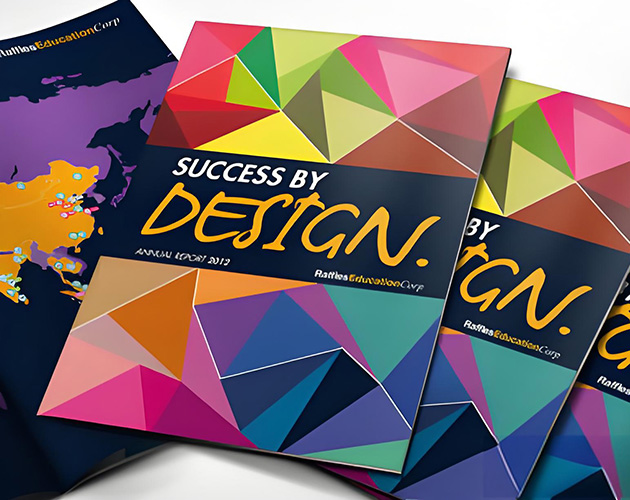

Founded in 2003, ZX China Industrial Limited is a trusted name in the printing industry, equipped with state-of-the-art facilities including Heidelberg and Mitsubishi 4-color printing machines. With these advanced technologies, we produce premium-quality, visually impressive printed products that include: Books, Booklets, Bibles, Brochures, Catalogues, Magazines, Hardcover Books, Newsletters, Lab ...[Details]

Popular Products

Our Features

What We Can Do

Offset printing, an indirect printing method, is named after early lithography, which initially used...

Screen printing refers to the use of a mesh screen as a printing plate, which is made into a screen ...

3D printing, also known as stereoscopic printing, typically refers to stereolithography printing. It...

Box Printing

-

Apparel Boxes -

Appliance Boxes -

Cosmetic Packaging Boxes -

Display Boxes -

Gift Packaging Boxes -

Jewelry Packaging Boxes -

Medicine Packaging Box -

Perfume Boxes -

Product Packaging Boxes -

Shoe Boxes

Bag Printing

Stationery Printing

Order for Business

Stuff

- Professional designs with added fizz

- Create an army of business stationery

- Take your attention to detail up a level

- Totally safe for laser printers

Printing Design Guidelines

-

What should be the bleed allowance for my artwork?

For books, folds, paper handbags, posters, flyers, folders, and cards, a bleed of 3mm is recommended, whereas for boxes, a bleed of 5mm is advisable.

-

What resolution does my artwork need to be for uploading?

Your artwork should be created at 300 dpi (dots per inch) or higher. If your artwork is at a lower resolution than this, the printing quality will be ...

-

Vector vs Bitmap Formats

Vector artwork employs a series of 'points' to define a shape, akin to a graph in mathematics. This ensures that any vector shape, at any resolution...

-

What types of files are accepted?

The best file format to submit your artwork in is Adobe Acrobat - pdf Please ensure you have followed these steps prior to sending the artwork : 1). C...

Printing Knowledge

-

Producing Casebound Books (Hardcover Books) 2014-02-24

The sequence of steps in binding hardcover books is shown in Figure 6-1. These steps remain the same whether books are bound by hand or by machine. FOLDING SIGNATURES AND ENDSHEETS. Large printed sheets are first folded to form signatures. A signature is a single sheet of paper folded to a certain number of pages. For ...

-

The Thickness of Printing Paper List 2013-09-05

Name Thickness/mm Name Thickness/mm 80gsm art paper 0.065 105gsm matt coated paper 0.09 105gsm art paper 0.085 128gsm matt coated paper 0.12 128gsm art paper 0.105 157gsm matt coated paper 0.16 157gsm art paper 0.135 200gsm matt coated paper 0.19 200gsm art paper 0.17 210gsm matt coated paper 0.21 210gsm art paper 0.19...

-

Perfect Binding - for booklet, catalog, book, magazine, etc. 2013-09-04

Perfect Binding Process Sewn Binding Process Perfect binding is often used, and gives a result similar to paperback books. National Geographic is one example of this type. Paperback or soft cover books are also normally bound using perfect binding. They usually consist of various sections with a cover made from heavier...

-

Saddle Stitch Binding - for booklet, catalog, magazine 2013-08-30

Fold the impression (cut or uncut) into several folds according to page number and sequence. The fold with multi-pages is called a signature of book-block. After collocating the folded signatures into volumes by order and combine them, it is called saddle stitching. Impression→folding→collating→wrappering→saddle st...

-

Glossy Art Paper - for booklet, catalog, flyer, poster, postcard, etc. 2013-08-29

Quality and rather heavy two-side coated printing paper with smooth surface. The reproduction of fine screen single- and multicolor pictures ("art on paper") requires a paper that has an even, well closed surface and a uniform ink absorption.

-

Black-and-White Line Art Plate-Making Techniques 2026-01-07

1. Traditional Plate-Making Traditionally, black-and-white line art plates are produced from black-ink originals or high-quality printed materials through photography, retouching, copying, and layout (or assembling). This method produces films that meet printing requirements but has a long production cycle, high costs,...

-

What Is DPI / PPI 2026-01-06

What Is DPI (Dots Per Inch) DPI stands for Dots Per Inch. It refers to the number of dots a printing or output device can place within one inch (2.54 cm). In the printing industry, DPI is mainly used to describe the output precision of printers and presses. The higher the DPI, the more dots are printed per inch, result...

-

Common Types of Hardcover Books and Cover Size Calculation 2026-01-05

Hardcover binding is one of the most refined binding methods in book publishing. Compared with paperback books, hardcovers feature superior materials, durable binding, elegant appearance, and better long-term preservation. 1. Common Types of Hardcover Binding 1.1 Classification by Spine Shape Square Spine A square spin...

-

The Impact of Prepress Imposition on the Binding Quality of Book and Magazine Printing 2025-12-31

Many critical details of the printing production process are determined during the prepress imposition stage, including the unification of trim and register marks for different jobs, the reservation of binding and milling margins, the standardization of process marks, and the handling of cross-spread and bleed images. ...

-

Techniques and Methods for Correcting Color Cast Caused by Insufficient Original Quality in Printing 2025-12-29

In the fields of book, magazine, and packaging printing, color printing has become the mainstream, and overall print quality has continuously improved. However, due to both subjective and objective factors, truly high-end printed products are still relatively rare and cannot yet fully match the quality of premium forei...